What is a Five Wishes Document?

Definition and Purpose

Five Wishes is a straightforward‚ legally valid document allowing individuals to express their healthcare preferences․

It’s designed for ease of understanding‚ focusing on personal values rather than complex medical jargon‚ available as a PDF․

The Importance of Advance Care Planning

Advance care planning ensures your wishes are honored if you’re unable to communicate them․

Utilizing a Five Wishes form proactively eases burdens on loved ones during challenging times‚ offering peace of mind․

The Five Wishes document is a carefully crafted‚ easily understandable advance directive designed to help individuals of all ages and medical backgrounds express their healthcare preferences․ Unlike traditional‚ often complex legal forms‚ Five Wishes uses plain language‚ focusing on what truly matters to you – your personal values and beliefs regarding medical treatment․

Available as a downloadable PDF‚ this document allows you to articulate your wishes concerning life-sustaining treatment‚ pain management‚ and the level of comfort you desire․ It’s more than just a legal form; it’s a conversation starter‚ encouraging meaningful discussions with family‚ friends‚ and your healthcare team․

The primary purpose of Five Wishes is to empower you to maintain control over your healthcare decisions‚ even when you are unable to speak for yourself․ It provides clear guidance to your appointed healthcare agent‚ ensuring your wishes are honored with respect and dignity․

Advance care planning‚ particularly through utilizing a document like Five Wishes (available as a PDF download)‚ is crucial for ensuring your healthcare wishes are respected․ It proactively addresses potential medical scenarios where you may be unable to communicate your decisions‚ safeguarding your autonomy and relieving potential burdens on your loved ones․

Without advance directives‚ critical healthcare choices may fall to family members during emotionally challenging times․ Five Wishes provides clear guidance‚ minimizing conflict and ensuring your values are central to the decision-making process․

Completing this PDF form isn’t merely about end-of-life care; it encompasses all healthcare decisions․ It’s a gift to your family‚ offering peace of mind knowing they are honoring your expressed desires‚ and a powerful act of self-determination․

Understanding the Sections of the Five Wishes PDF

The Five Wishes PDF is structured into five key sections‚ each addressing a vital aspect of your healthcare preferences and personal values․

Wish 1: Who I Want to Make Decisions for Me

Wish 1 of the Five Wishes document focuses on appointing a healthcare proxy – the person you trust to make medical decisions on your behalf if you become unable to do so․ This section requires careful consideration‚ as this individual will advocate for your wishes as expressed in the document․

You’ll need to clearly name your healthcare proxy and also designate an alternate‚ in case your first choice is unavailable․ The PDF form provides space to include their full contact information․ It’s crucial to discuss your values and preferences with both individuals to ensure they understand and are comfortable fulfilling this important role․

This isn’t simply about medical choices; it’s about ensuring someone understands what matters most to you regarding your overall well-being and quality of life․ Properly completing Wish 1 is foundational to the entire document’s effectiveness․

Wish 2: What Kind of Medical Treatment I Want

Wish 2 within the Five Wishes PDF allows you to articulate your preferences regarding specific medical treatments․ This section moves beyond simply naming a proxy and delves into the types of care you would or would not want to receive in various situations․

The document presents options relating to life-sustaining treatments like CPR‚ mechanical ventilation‚ and artificial nutrition/hydration․ You can indicate your choices using a simple check-box format‚ specifying whether you want these treatments provided‚ withheld‚ or deferred to your healthcare proxy’s discretion․

This wish is designed to be accessible‚ avoiding complex medical terminology․ It empowers you to clearly state your values concerning prolonging life versus prioritizing comfort and dignity‚ ensuring your care aligns with your personal beliefs․

Wish 3: What Comfort I Want

Wish 3‚ detailed within the Five Wishes PDF‚ focuses on your preferences for pain relief and overall comfort care․ This section acknowledges that even when a cure isn’t possible‚ maintaining quality of life is paramount․ It allows you to express your desires regarding pain management‚ symptom control‚ and emotional support․

The form prompts you to consider what constitutes a comfortable existence‚ addressing aspects like being kept free from pain‚ having a peaceful environment‚ and receiving spiritual or emotional support․ You can specify your wishes for things like music‚ visits from loved ones‚ or religious practices․

This wish emphasizes holistic care‚ recognizing the importance of addressing physical‚ emotional‚ and spiritual needs during serious illness‚ ensuring your final days are as peaceful and dignified as possible․

Wish 4: How I Want to Be Remembered

Wish 4‚ found within the Five Wishes PDF‚ is a uniquely personal section focusing on your legacy and how you wish to be remembered by loved ones․ It moves beyond medical directives to address your emotional and spiritual desires regarding your final farewell․ This section allows you to express preferences for funeral arrangements‚ memorial services‚ or other ways you’d like to be honored․

You can detail specific requests‚ such as music choices‚ readings‚ or charitable donations in your name․ It’s a space to share values‚ beliefs‚ or stories you want to be passed down to future generations․

This wish provides comfort to both you and your family‚ ensuring your life is celebrated in a way that truly reflects who you were․

Wish 5: Other Wishes

Wish 5‚ within the Five Wishes PDF‚ serves as a crucial catch-all for any preferences not covered in the preceding sections․ It’s a space for expressing personal desires related to your care‚ comfort‚ or final arrangements․ This section allows for details regarding spiritual practices‚ pet care‚ or specific belongings you wish to distribute․

You can articulate preferences for visitors‚ communication methods‚ or even simple comforts like having a favorite blanket nearby․ It’s an opportunity to address unique needs or concerns that are important to you‚ ensuring a more personalized care experience․

This final wish reinforces your autonomy and provides clarity for your healthcare team and family․

Accessing and Downloading the Five Wishes PDF

Official Sources for the Document

The Five Wishes PDF is readily available through the official Aging with Dignity website‚ ensuring you obtain a current‚ legally sound version․

Cost and Availability

While a free downloadable order form exists‚ obtaining the complete PDF typically involves a purchase‚ supporting the organization’s mission․

Accessing the authentic Five Wishes document is crucial for ensuring its legal validity and accuracy․ The primary and most reliable source is the Aging with Dignity website (agingwithdignity․org)․ This platform provides direct access to the official PDF version‚ guaranteeing you receive the most up-to-date iteration of the form․

Downloading directly from Aging with Dignity safeguards against potentially outdated or altered versions circulating online․ They offer clear instructions and support resources alongside the document․ Be cautious of third-party websites offering downloads‚ as their authenticity cannot always be verified․ Utilizing the official source ensures your Five Wishes document will be recognized and respected by healthcare professionals and legal authorities․

Furthermore‚ Aging with Dignity frequently updates the document to reflect changes in healthcare laws and best practices‚ making their website the definitive location for obtaining a legally sound Five Wishes PDF․

The Five Wishes document is readily available for purchase‚ though not typically offered as a free download in its complete‚ legally-recognized form․ A single copy of the PDF can be obtained for a nominal fee‚ generally around $5․00‚ directly from the Aging with Dignity website (agingwithdignity․org)․ Bulk discounts are often available for organizations or individuals needing multiple copies․

This modest cost supports Aging with Dignity’s mission of promoting advance care planning and providing educational resources․ While some introductory materials or sample sections might be found freely online‚ the official‚ legally-binding PDF requires purchase․ The document is instantly accessible after purchase‚ allowing immediate download and completion․

Physical copies can also be ordered‚ incurring additional shipping costs․ The widespread availability ensures accessibility for individuals seeking to document their healthcare preferences․

Completing the Five Wishes Document

Witness Requirements and Legal Validity

Five Wishes requires two adult witnesses‚ not relatives‚ to attest to your signature‚ ensuring legal validity of the PDF form․

Specific Instructions for Filling Out the Form

Carefully read and complete each section of the Five Wishes PDF‚ using black ink and following the provided guidelines for clarity․

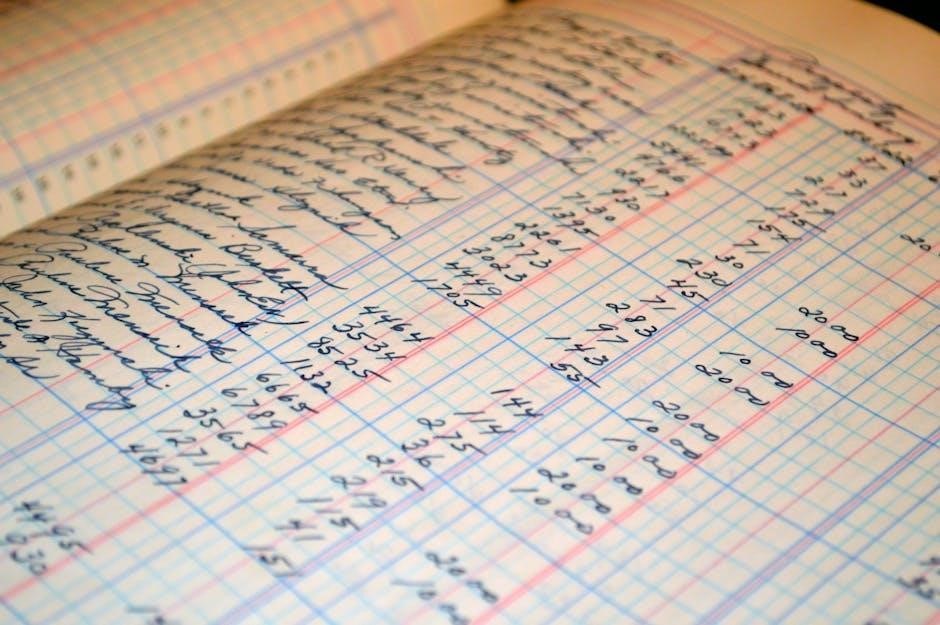

Five Wishes‚ as a legally recognized advance directive‚ necessitates specific witness requirements to ensure its validity and enforceability․ The document must be signed in the presence of two adult witnesses who are not directly involved in your healthcare‚ meaning they cannot be your healthcare provider‚ a paid caregiver‚ or a relative by blood or marriage․

These witnesses are required to attest that you appeared to be of sound mind and were not under duress or undue influence when signing the PDF form․ They must also sign and date the document themselves‚ providing their printed names and addresses․ It’s crucial to verify that all witness information is accurately recorded․

Failure to adhere to these witness requirements could render your Five Wishes document legally invalid‚ potentially negating your expressed healthcare preferences․ Therefore‚ meticulous attention to detail during the signing process is paramount․ Always retain a copy of the completed and witnessed document for your records․

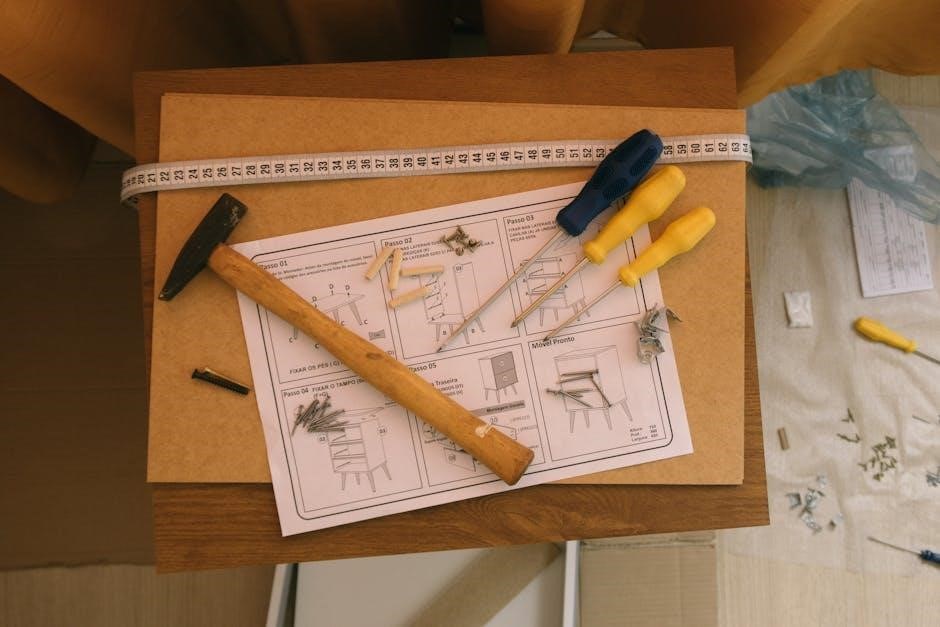

When completing the Five Wishes PDF‚ use black or blue ink for clarity and legibility․ Begin by carefully reading the introduction and instructions provided within the document․ Each “Wish” section offers specific prompts; answer honestly and thoroughly‚ reflecting your personal values and preferences․

For Wish 1‚ designate your healthcare agent and an alternate․ Wish 2 details your treatment preferences‚ including life-sustaining measures․ Wish 3 focuses on comfort care‚ specifying pain management and other supportive treatments․ Wish 4 allows you to express how you wish to be remembered‚ offering guidance to loved ones․

Wish 5 provides space for any additional wishes not covered elsewhere․ Ensure all sections are completed to the best of your ability․ Review the entire PDF before signing and dating it in the presence of the required witnesses․

Five Wishes and FiveM (Clarification)

Distinguishing Advance Care Planning from Gaming Platforms

Five Wishes‚ a healthcare document PDF‚ is unrelated to the online gaming platform FiveM; they share a name causing potential confusion online․

Why the Terms Might Be Confused Online

Internet searches can conflate these terms‚ but Five Wishes concerns end-of-life care‚ while FiveM is a Grand Theft Auto V modification platform․

It’s crucial to understand that Five Wishes‚ the advance care planning document often available as a PDF download‚ exists in a completely separate realm from FiveM․ FiveM is a popular modification framework for the video game Grand Theft Auto V‚ enabling players to create and join custom multiplayer servers․ The similarity in names frequently leads to unintentional conflation during online searches and discussions․

Five Wishes focuses on deeply personal and sensitive decisions regarding your future healthcare‚ outlining your preferences for medical treatment and end-of-life care; Conversely‚ FiveM is purely entertainment-focused‚ centered around roleplaying and customized gaming experiences․ Recognizing this fundamental difference is vital to avoid confusion and ensure you’re accessing the correct information when seeking resources related to either topic․ One concerns legal and medical wellbeing‚ the other‚ virtual recreation․

The online confusion between “Five Wishes” – the advance care planning document‚ often found as a PDF – and “FiveM” stems primarily from identical naming․ Search engines‚ lacking context‚ often present results for both when a user enters “Five Wishes” or related keywords․ This is exacerbated by online forums and communities where discussions about both topics may coexist‚ leading to cross-contamination of information․

Furthermore‚ individuals seeking the Five Wishes PDF may inadvertently land on FiveM-related websites‚ and vice versa․ The prevalence of gaming content online also contributes to this issue‚ overshadowing resources for healthcare planning․ Therefore‚ it’s essential to use precise search terms like “Five Wishes advance directive PDF” to refine results and locate the correct document for your needs‚ avoiding the gaming platform․

Legal Considerations for Five Wishes

State-Specific Laws and Recognition

Five Wishes is legally valid in most states‚ but specific regulations vary; review your state’s laws before completing the PDF form․

Combining Five Wishes with a Living Will or Healthcare Proxy

Five Wishes can complement or replace a living will/healthcare proxy‚ offering a comprehensive approach to advance care planning‚ documented in a PDF․

Five Wishes enjoys broad legal recognition across the United States‚ however‚ it’s crucial to understand that healthcare laws are primarily governed at the state level․ While the document is designed to be widely accepted‚ specific interpretations and requirements can differ significantly from one state to another․ Before finalizing your Five Wishes PDF‚ it’s highly recommended to verify its validity and any specific stipulations within your state of residence․

Some states may have specific formatting requirements or necessitate additional documentation to ensure the document’s enforceability․ Resources like the American Academy of Estate Planning Attorneys or your state’s bar association can provide valuable guidance․ Understanding these nuances ensures your healthcare preferences‚ as expressed in the Five Wishes document‚ will be legally honored when you are unable to advocate for yourself․ Always prioritize state-specific legal counsel for optimal protection․

The Five Wishes document often serves as a comprehensive alternative to traditional advance directives like a Living Will or Healthcare Proxy‚ but they can also be used in conjunction․ A Living Will typically focuses on specific medical treatments you wish to accept or refuse‚ while a Healthcare Proxy designates someone to make decisions on your behalf․

The Five Wishes PDF uniquely combines elements of both‚ addressing values‚ treatment preferences‚ and appointing a healthcare agent․ You might choose to use Five Wishes instead of separate documents‚ or supplement it with a Healthcare Proxy for broader decision-making authority․ Consulting with an attorney ensures your documents work harmoniously‚ avoiding conflicts and clearly reflecting your overall healthcare wishes; Proper coordination provides the most robust protection․

Resources and Support for Advance Care Planning

Organizations Offering Assistance

Numerous organizations provide guidance on advance care planning and the Five Wishes PDF․ They offer support and resources for completing your document effectively․

Additional Online Resources

Explore online platforms for downloadable forms‚ FAQs‚ and state-specific information regarding advance directives and the Five Wishes document․

Several dedicated organizations are readily available to assist individuals navigating the process of advance care planning and utilizing the Five Wishes PDF․ Aging with Dignity‚ the creator of Five Wishes‚ provides comprehensive support‚ including guidance on completing the document and understanding its legal implications․ Their website offers a wealth of information and resources‚ ensuring individuals feel empowered to make informed decisions about their future healthcare․

The National Hospice and Palliative Care Organization (NHPCO) is another valuable resource‚ offering information on advance care planning and connecting individuals with local hospice and palliative care providers․ These providers can offer personalized support and guidance․ Additionally‚ many state-specific organizations and coalitions focus on end-of-life care and advance directives‚ providing tailored resources and assistance to residents within their respective states․ These groups often host workshops and seminars to educate the public about the importance of advance care planning and the benefits of completing a Five Wishes document․

Numerous online platforms offer valuable information and support regarding the Five Wishes PDF and advance care planning․ The official Aging with Dignity website (https://www․fivewishes․org/) serves as a central hub‚ providing access to the document‚ FAQs‚ and state-specific resources․ Explore websites like PrepareYourCare‚ offering guides and tools to facilitate conversations about healthcare preferences․

CaringInfo‚ a service of the National Hospice and Palliative Care Organization‚ provides state-specific advance directive forms and information․ Many hospitals and healthcare systems also offer online resources and downloadable PDFs related to advance care planning․ YouTube features numerous videos explaining the Five Wishes document and the importance of completing it․ Remember to verify the credibility of any online source before relying on its information‚ ensuring it aligns with legal requirements in your state․ Utilizing these resources empowers individuals to proactively plan for their future healthcare needs․