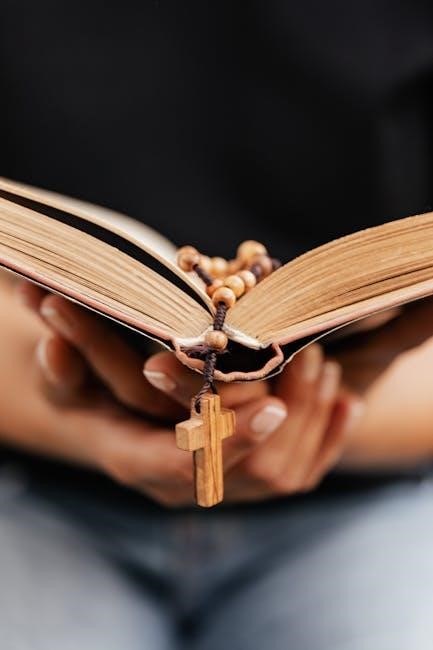

Discover the transformative power of praying God’s Word over your children. Jodie Berndt’s book guides parents in aligning prayers with Scripture‚ fostering faith and intimacy with God.

Why Praying the Scriptures is Powerful

Praying the Scriptures is powerful because it aligns your prayers with God’s will‚ building faith as you claim His promises for your children. By using biblical truths‚ you invite God’s power and wisdom into their lives‚ ensuring your prayers are effective and rooted in His Word. This method fosters perseverance in prayer and trust in God’s faithfulness. As you pray Scripture‚ you anchor your requests in His unchanging truth‚ knowing His Word will accomplish its purpose in their lives. This practice deepens your relationship with God and shapes your children’s spiritual journey‚ leaving a lasting legacy of faith.

The Importance of Using God’s Word in Prayer

Using God’s Word in prayer ensures your requests are aligned with His will‚ making them more effective. Scripture praying grounds your prayers in divine truth‚ providing clarity and confidence. It helps overcome uncertainty about what to pray‚ as you rely on God’s promises. Praying His Word also strengthens your faith‚ as you declare His truths over your children’s lives. This practice invites the Holy Spirit to work powerfully‚ transforming their hearts and circumstances. By praying Scripture‚ you create a spiritual legacy‚ imparting God’s promises to the next generation and equipping them to trust Him fully. His Word is life-changing and eternal.

Understanding the Concept of Scripture Praying

Scripture praying involves inserting your child’s name into biblical verses‚ personalizing God’s promises for their life‚ and praying them back to Him for guidance and protection.

What Scripture Praying Means

Scripture praying is a powerful practice where parents use Bible verses as the foundation for their prayers‚ inserting their child’s name to personalize God’s promises. This method aligns prayers with God’s will‚ fostering faith and intimacy. By praying Scriptures‚ parents claim divine promises for their children’s lives‚ seeking guidance‚ protection‚ and spiritual growth. It’s a partnership with God‚ using His Word to shape prayers that are both meaningful and effective‚ ensuring that children are covered in His truth and love. This approach strengthens parental faith and equips children to stand firmly in their Christian identity.

How to Apply Scripture Praying in Daily Life

Applying Scripture praying daily involves personalizing God’s Word for your child. Start by selecting specific verses that address their needs‚ such as salvation‚ wisdom‚ or protection. Insert your child’s name into the Scripture‚ making it a heartfelt‚ targeted prayer. Dedicate a few minutes each day to pray these verses aloud or in your heart. Consistency is key‚ so create a routine‚ such as praying during morning devotion or bedtime. Over time‚ this practice deepens your faith and helps your child grow in God’s truth. Additionally‚ encourage your child to join in‚ teaching them to pray Scripture for themselves.

Getting Started with Praying the Scriptures

Begin by identifying key Scriptures for your child‚ personalizing prayers with their name‚ and creating a prayer bank for consistent‚ impactful prayer guided by God’s Word.

Identifying Key Scriptures for Your Child

Identifying key Scriptures for your child involves seeking verses that address their specific needs‚ such as salvation‚ wisdom‚ protection‚ and emotional well-being. Start by reflecting on your child’s life‚ considering areas where they may need guidance or encouragement. Use a concordance or Bible app to find relevant passages. For example‚ Psalm 91 offers protection‚ while Proverbs 3:5-6 provides wisdom. Personalize these verses by inserting your child’s name‚ making the prayers more intimate and meaningful. This approach ensures your prayers align with God’s promises‚ fostering faith and trust in His plan for their lives. Consistency in using these Scriptures strengthens your prayer life and your child’s spiritual foundation.

Personalizing Prayers with Your Child’s Name

Personalizing prayers with your child’s name makes them more intimate and meaningful. Inserting their name into specific Scriptures creates a powerful connection to God’s promises. For example‚ pray Psalm 91:2 over them: “Lord‚ You are my child’s refuge and shelter.” This method helps parents pray with clarity and confidence‚ knowing they are aligning their requests with God’s Word. Personalized prayers also deepen your child’s understanding of God’s love and purpose for their life. By tailoring verses like Proverbs 3:5-6‚ you guide them toward wisdom and trust in God. This practice fosters a strong spiritual foundation and demonstrates your love and care. Consistency strengthens both your prayer life and their faith journey.

Creating a Prayer Bank for Your Child

A prayer bank is a collection of meaningful Scriptures and prayers tailored for your child. Start by compiling verses that address specific areas of their life‚ such as salvation‚ wisdom‚ and protection. Write down personalized prayers using their name‚ ensuring each request aligns with God’s Word. Encourage your child to participate by selecting verses they feel drawn to. This collaborative effort helps them understand the power of prayer and fosters a deeper connection with God. Regularly updating the prayer bank keeps prayers fresh and relevant. Over time‚ it becomes a cherished spiritual legacy‚ guiding your child in their faith journey.

Praying for Your Child’s Salvation

Pray for your child’s spiritual awakening‚ asking God to turn their heart from darkness to light‚ granting forgiveness and redemption through Christ‚ aligning with His will.

Scriptures to Pray for Spiritual Awakening

Pray for your child’s spiritual awakening using Scriptures like Psalm 119:25‚ which revives their spirit‚ and Ephesians 1:18‚ to enlighten their heart to God’s hope. Use 2 Corinthians 4:6 to ask God to shine His light into their soul. Incorporate verses that speak of salvation‚ such as Acts 26:18‚ to turn their darkness to light. Insert your child’s name into these prayers‚ asking God to reveal Himself and draw them to Christ. These Scriptures empower your prayers‚ aligning them with God’s will for their spiritual transformation and eternal life. Consistent prayer fosters a deep‚ personal relationship with Jesus‚ guiding their spiritual journey.

Praying for Forgiveness and Redemption

Pray for your child’s forgiveness and redemption by using Scriptures like Acts 26:18‚ asking God to turn them from darkness to light. Incorporate verses such as Psalm 51:10-12‚ seeking a pure heart and cleansing from sin. Personalize prayers by inserting your child’s name‚ asking for deliverance from sin and a deep understanding of God’s mercy. Pray for redemption‚ that they may know Jesus as their Savior and live in His freedom. These prayers align with God’s desire for their salvation and spiritual transformation‚ bringing hope and assurance of eternal life through His grace and forgiveness.

Praying for Wisdom and Discernment

Pray for your child to seek wisdom in decisions and discern God’s will. Use Scriptures like Proverbs 3:5-6 and James 1:5 to guide their path and choices.

Scriptures for Guidance in Decision-Making

Praying Scriptures like Proverbs 3:5-6 and James 1:5 can guide your child in decision-making. Proverbs 3:5-6 reminds us to trust God with all our heart and lean not on our own understanding‚ while James 1:5 promises wisdom for those who ask. Pray Psalm 119:105‚ asking God to make His Word a lamp to their feet and a light to their path. Insert your child’s name into these verses‚ asking God to grant them clarity and discernment. This practice helps build their faith and equips them to make choices aligned with God’s will‚ fostering wisdom and confidence in their lives.

Praying for Wisdom in Challenging Situations

When your child faces difficult situations‚ pray Philippians 1:9-11‚ asking God to fill them with wisdom and discernment. Insert their name into the verse‚ pleading for their love to abound in knowledge and depth of insight. Pray that they would distinguish good from evil and be pure and blameless. Use Psalm 119:66‚ requesting that God teach them His statutes and grant them understanding. Praying these Scriptures helps your child navigate challenges with God’s wisdom‚ equipping them to make sound decisions and remain steadfast in their faith‚ even in uncertain times. This builds their trust in God’s plan and provision.

Praying for Protection and Safety

Pray God’s promises for your child’s protection‚ using Scriptures like Psalm 91. Plead for a shield of faith‚ safety‚ and peace‚ trusting in His divine care always.

Scriptures for Physical and Spiritual Protection

Psalm 91 offers powerful promises for protection‚ declaring God as a refuge and shield. Pray verses like Psalm 91:11‚ asking for angelic protection over your child. Use Proverbs 2:6-7 to pray for wisdom and safety in decisions. Isaiah 54:17 assures victory over every challenge‚ while Psalm 121 emphasizes God’s watchful care. Pray these Scriptures faithfully‚ trusting in God’s faithfulness to guard your child’s physical and spiritual well-being. Allow His Word to bring comfort and assurance as you intercede for their safety and security in all areas of life.

Praying Psalm 91 Over Your Child

Psalm 91 is a powerful prayer for protection‚ promising God’s refuge and shield over your child. Pray verses like Psalm 91:4‚ asking God to cover your child under His wings. Use Psalm 91:11 to petition for angelic protection in every situation. Claim the assurance of Psalm 91:16‚ trusting in God’s faithfulness to be with your child always. Personalize these verses by inserting your child’s name‚ declaring God’s promises over their life. This practice fosters trust in God’s sovereignty and provides comfort‚ knowing He is their ultimate protector. Praying Psalm 91 over your child is a profound way to seek His safety and peace.

Praying for Emotional and Mental Well-Being

Pray Scriptures like Psalm 91 for peace and comfort‚ asking God to fill your child with emotional stability and joy. Trust Him to bring calmness and hope.

Scriptures for Peace and Comfort

Praying Scriptures like Psalm 91 brings peace and comfort to your children. Verse 2 declares‚ “I will say of the Lord‚ ‘He is my refuge and my fortress‚ my God‚ in whom I trust;’”

Isaiah 26:3 promises‚ “You will keep in perfect peace those whose minds are steadfast‚ because they trust in you.” Pray this over your child to fill them with calmness and hope.

Philippians 4:7 assures‚ “And the peace of God‚ which transcends all understanding‚ will guard your hearts and minds in Christ Jesus.” Trust God to bring emotional stability and joy to your child’s life.

Praying for Emotional Stability and Joy

Pray Galatians 5:22-23 over your child: “But the fruit of the Spirit is love‚ joy‚ peace‚ patience‚ kindness‚ goodness‚ faithfulness‚ gentleness‚ and self-control.” Ask God to cultivate these qualities in their life.

Use 1 Peter 5:7‚ “Cast all your anxieties on him‚ for he cares for you‚” to pray for emotional stability and trust in God’s care for their well-being.

Pray Proverbs 17:22‚ “A joyful heart is good medicine‚” asking God to fill your child with genuine joy that overflows into all areas of their life and brings healing from sorrow or unrest.

Praying for Relationships and Friendships

Pray Proverbs 27:9‚ “A friend loves at all times‚” asking God to surround your child with loyal‚ loving friends who encourage their walk with Christ.

Pray Proverbs 22:24-25‚ “Do not make friends with a hot-tempered person…‚” seeking wisdom for your child to choose godly companions and build healthy relationships.

Scriptures for Healthy Relationships

Praying for healthy relationships involves using God’s Word to guide your child in building strong‚ godly connections. Pray Proverbs 27:9‚ which says‚ “A friend loves at all times‚” asking God to surround your child with loyal and loving friends who encourage their walk with Christ.

Use Proverbs 22:24-25‚ “Do not make friends with a hot-tempered person…‚” to pray for wisdom in choosing friends and avoiding harmful influences. Also‚ pray Psalm 119:133‚ “Direct my steps by your word!” to guide their interactions and relationships.

Commit your child’s relationships to God‚ trusting Him to bring people into their life who will edify and support their spiritual growth.

Praying for Positive Influences in Their Lives

Praying for positive influences in your child’s life involves asking God to surround them with people who will encourage their spiritual growth and godly character. Use Proverbs 13:20‚ “Walk with the wise and become wise‚” to pray for wise mentors and friends who will guide them rightly. Pray Psalm 1:1-3‚ asking God to keep your child from ungodly influences and to help them delight in His Word. Pray that your child will be drawn to people who love God and reflect His love‚ creating a supportive and uplifting environment for their spiritual journey.

Praying for Academic and Personal Success

Praying for academic and personal success involves seeking God’s wisdom and provision. Use Proverbs 2:6 and Proverbs 10:14 to pray for knowledge‚ understanding‚ and guidance in their studies and life decisions.

Scriptures for Academic Excellence

Praying for academic excellence involves using specific Scriptures to guide your child’s educational journey. Proverbs 2:6 declares‚ “For the Lord gives wisdom‚ and from His mouth come knowledge and understanding.” Pray this verse to seek divine wisdom for your child’s studies. Additionally‚ Proverbs 10:14 emphasizes the importance of knowledge and discretion‚ urging parents to pray for their child’s ability to apply what they learn. Philippians 4:13 reminds us that all things‚ including academic tasks‚ can be accomplished through Christ who strengthens us. Use these verses to pray for clarity‚ focus‚ and success in your child’s academic pursuits.

Praying for Passion and Purpose in Life

Praying for your child to discover their passion and purpose involves asking God to reveal His plan for their life. Use Jeremiah 29:11‚ which promises‚ “For I know the plans I have for you… plans to prosper you and not to harm you‚ plans to give you hope and a future.” Pray this verse over your child‚ asking God to ignite their passions and guide their steps. Additionally‚ Proverbs 16:9 reminds us that while we may plan our course‚ the Lord establishes our steps. Pray for your child to seek God’s will and find joy and fulfillment in His purpose for their life.

Praying for Spiritual Growth and Maturity

Pray for your child to grow spiritually‚ asking God to strengthen their faith‚ deepen their understanding of His love‚ and grant them wisdom to live according to His will.

Scriptures for a Deepening Faith

Praying Scriptures like Psalm 91 and Proverbs 3:5-6 over your children nurtures their faith. These verses remind them of God’s protection and guidance. Use passages like Romans 12:2 to pray for their minds to be transformed and aligned with God’s will. Verses such as Jeremiah 29:11 and Isaiah 40:31 emphasize hope and trust in God’s plans. Incorporate Scriptures that highlight God’s love‚ such as John 3:16‚ to deepen their understanding of His character. Regularly praying these verses helps your child build a strong spiritual foundation and fosters a lifelong relationship with Christ.

Praying for a Heart of Worship and Service

Praying Scriptures that cultivate a heart of worship and service in your children is vital. Use verses like Psalm 100:4-5‚ which encourages thanksgiving and praise‚ to pray for their hearts to overflow with gratitude. Pray Matthew 5:16 to guide them in letting their light shine through acts of service. Verses such as 1 Chronicles 16:28-29 and Psalm 95:6-7 teach them to worship in humility and surrender. Praying these Scriptures helps your child develop a lifelong passion for glorifying God and serving others with humility‚ aligning their hearts with His will and purpose.

Praying with Your Children

Teach children to pray Scripture‚ fostering a heart of worship. Create a prayer bank together‚ guiding them to intercede for others. Foster a legacy of prayer and faith.

How to Involve Your Children in Scripture Praying

Engage your children in Scripture praying by teaching them to insert their name or others’ names into biblical verses. Start with simple Scriptures like Psalm 91 or Proverbs 3:5-6‚ making it relatable. Encourage them to pray for friends‚ family‚ or even themselves; Demonstrate how to personalize prayers‚ such as‚ “Lord‚ help [name] trust in You with all their heart.” Create a prayer bank with verses they can use. Make it a family activity‚ fostering a deeper connection with God. As they grow‚ guide them in applying Scripture to real-life challenges‚ helping them develop a lifelong habit of prayer rooted in God’s Word.

Building a Prayer Legacy Together

Creating a prayer legacy with your children fosters a lifelong connection with God. Start by modeling prayer habits and involving them in Scripture praying. Encourage them to write down verses and reflect on how God answers. Share family prayer stories‚ showing His faithfulness. Teach them to pray for others‚ building compassion. As they grow‚ guide them in leading prayers‚ nurturing leadership. Consistency is key—pray together regularly‚ even briefly. Over time‚ this practice becomes a cherished tradition‚ leaving a spiritual heritage for generations. Praying together strengthens bonds and deepens faith‚ creating a lasting impact on their lives and future families.

Resources for Praying the Scriptures

Jodie Berndt’s book and prayer cards offer practical tools for praying Scripture over children. Additional guides and verses provide further inspiration and direction for meaningful prayer.

The Book “Praying the Scriptures for Your Children”

Jodie Berndt’s book‚ Praying the Scriptures for Your Children‚ offers a comprehensive guide to praying God’s Word over your children. This 20th Anniversary Edition provides practical tools‚ including prayer cards and detailed guides‚ to help parents align their prayers with Scripture. Berndt shares simple yet powerful principles that transform prayer lives‚ encouraging parents to pray for their children’s salvation‚ emotional well-being‚ and spiritual growth. The book includes specific Scriptures and real-life examples‚ making it an invaluable resource for fostering faith and intimacy with God. Its insights have empowered countless parents to pray effectively and confidently for their children’s lives.

Additional Scriptures and Prayer Guides

Beyond the book‚ Jodie Berndt offers additional resources to deepen your prayer practice. These include downloadable prayer cards‚ Scripture guides‚ and a prayer bank template. Psalm 37:3-5‚ 138:8‚ and 112:1-7 are highlighted for trusting God‚ guidance‚ and integrity. Parents can use these verses to craft personalized prayers‚ inserting their child’s name for a meaningful connection. The resources emphasize praying for character‚ wisdom‚ and purpose‚ encouraging consistent and intentional prayer. With these tools‚ families can create a structured approach to praying the Scriptures‚ ensuring every area of their children’s lives is covered in prayer.

Consistently praying the Scriptures transforms lives‚ fostering spiritual growth and peace. Jodie Berndt’s resources empower parents to trust God’s plan‚ ensuring lasting impact and eternal blessings for their children.

The Impact of Consistent Scripture Praying

Consistent Scripture praying fosters deep spiritual growth in children‚ aligning their lives with God’s promises. By praying God’s Word‚ parents build their children’s faith‚ guiding them toward purity‚ wisdom‚ and purpose. This practice strengthens relationships‚ equips them for challenges‚ and brings comfort in difficult times. Over time‚ it cultivates a heart of worship and service‚ leaving a lasting prayer legacy that influences future generations. The power of Scripture praying transforms not only the child but also the praying parent‚ creating a ripple effect of God’s love and truth in their lives and beyond.

Encouragement to Continue Praying for Your Children

Praying the Scriptures for your children is a lifelong journey that brings hope‚ comfort‚ and transformation. As you persist in prayer‚ you witness God’s promises unfolding in their lives‚ fostering their faith and character. Encouragement comes from seeing spiritual growth‚ wisdom‚ and resilience in your children. Remember‚ every prayer is an investment in their eternal destiny. Trust in God’s faithfulness and continue to pray His Word over them‚ knowing He is always at work. Your consistent prayers will leave a lasting legacy of love and faith for generations to come. Keep praying—God hears and answers!