PVC pipe fittings are essential components in plumbing systems‚ offering durability and corrosion resistance. Made from polyvinyl chloride‚ they are widely used for water supply and drainage. A PDF guide provides detailed names and images of common fittings‚ aiding professionals and DIY enthusiasts in identifying and selecting the right components for their projects.

Overview of PVC Pipe Fittings

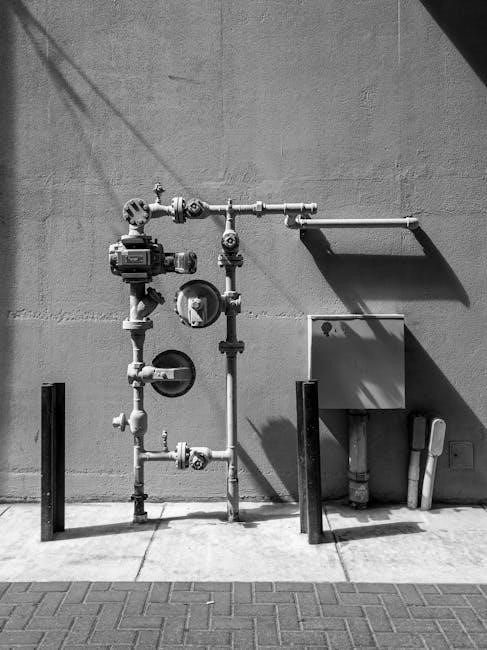

PVC pipe fittings are versatile components used in plumbing and piping systems to connect‚ redirect‚ or regulate the flow of fluids. They are made from polyvinyl chloride‚ a durable and corrosion-resistant material‚ making them ideal for water supply‚ drainage‚ and industrial applications. Common types include tees‚ elbows‚ couplings‚ adapters‚ valves‚ bends‚ reducers‚ caps‚ plugs‚ unions‚ and flanges‚ each serving specific functions. These fittings are available in various sizes and pressure ratings‚ ensuring compatibility with different systems; Resources like PDF guides and manufacturer catalogs provide detailed names and images of PVC pipe fittings‚ helping professionals and DIY enthusiasts identify and select the right components for their projects. Their lightweight and easy installation make them a preferred choice in modern plumbing solutions.

Importance of PVC Pipe Fittings in Plumbing Systems

PVC pipe fittings are crucial in plumbing systems due to their durability‚ corrosion resistance‚ and versatility. They ensure reliable connections‚ redirects‚ and flow regulation‚ minimizing leaks and system failures. Their resistance to chemicals and weathering makes them ideal for both indoor and outdoor applications. Lightweight and easy to install‚ PVC fittings reduce labor costs and installation time. They are widely used in water supply‚ drainage‚ and irrigation systems‚ offering a cost-effective alternative to metal fittings. Resources like PDF guides and catalogs provide detailed names and images of these fittings‚ aiding professionals in selecting the right components. Their adaptability and performance make them indispensable in modern plumbing‚ ensuring long-lasting and efficient systems.

Types of PVC Pipe Fittings

PVC pipe fittings include tees‚ elbows‚ couplings‚ adapters‚ valves‚ bends‚ reducers‚ caps‚ plugs‚ unions‚ and flanges. Each serves specific functions‚ ensuring efficient plumbing connections and system versatility.

Tees

Tees are a common type of PVC pipe fitting used to connect three pipes‚ allowing water to flow in multiple directions. They are available in equal and unequal sizes‚ with equal tees having all three openings of the same diameter. Unequal tees‚ on the other hand‚ have different sized openings to accommodate varying pipe sizes. Tees are often used in plumbing systems to create branch lines or to redirect water flow. They are durable‚ corrosion-resistant‚ and suitable for both underground and above-ground applications. When installing tees‚ proper alignment and solvent welding are essential to ensure leak-free connections. Tees are widely used in residential‚ commercial‚ and industrial plumbing systems‚ making them a versatile and essential fitting for various piping needs.

Elbows

Elbows are PVC pipe fittings designed to change the direction of a pipe run. They are available in various angles‚ with the most common being 45°‚ 90°‚ and 180°. These fittings are essential for routing pipes around obstacles or adjusting the layout of plumbing systems. Elbows are durable and resistant to corrosion‚ making them suitable for both underground and above-ground installations. They are commonly used in water supply‚ drainage‚ and irrigation systems. When installing elbows‚ proper alignment and solvent welding are crucial to ensure a leak-free connection. Elbows are also available in different sizes to accommodate various pipe diameters‚ ensuring flexibility in plumbing designs. Their versatility and reliability make them a fundamental component in PVC piping systems.

Couplings

Couplings are PVC pipe fittings used to connect two pipes together‚ ensuring a secure and leak-free joint. They are available in different types‚ including socket‚ threaded‚ and flanged couplings. Socket couplings are the most common and are joined using solvent welding‚ while threaded and flanged couplings provide additional flexibility for specific applications. Couplings are designed to handle various pressure ratings and are suitable for both underground and above-ground installations. They are commonly used in water supply‚ drainage‚ and irrigation systems. Proper sizing and alignment are crucial to ensure optimal performance. Couplings are durable and resistant to corrosion‚ making them a reliable choice for PVC piping systems. Their versatility and ease of installation make them an essential component in modern plumbing.

Adapters

Adapters are versatile PVC pipe fittings designed to connect pipes of different sizes or types. They are available in various configurations‚ such as male and female threads‚ socket to spigot‚ and flanged adapters. These fittings enable transitions between PVC pipes and other materials like copper or steel‚ making them ideal for system integration. Adapters are commonly used in plumbing‚ irrigation‚ and industrial applications where pipe size or type changes are necessary. They are resistant to corrosion and can withstand various pressure ratings‚ ensuring reliability in diverse environments. Proper selection of adapters is crucial to maintain system integrity and prevent leaks. Their durability and ease of installation make them a key component in modern piping systems‚ providing a seamless connection between different pipe specifications and materials.

Valves

Valves are critical PVC pipe fittings used to control the flow of fluids in plumbing and industrial systems. They are designed to regulate‚ direct‚ or stop the flow of liquids or gases. PVC valves are known for their corrosion resistance‚ durability‚ and lightweight construction‚ making them ideal for water supply‚ drainage‚ and chemical handling applications. Common types include ball valves‚ gate valves‚ and check valves‚ each serving specific purposes. Ball valves offer precise flow control‚ while gate valves are used for on/off functionality. Check valves prevent backflow‚ ensuring system safety. PVC valves are available in various pressure ratings‚ such as 6 kg/cm²‚ and are easy to install and maintain. Their chemical resistance and affordability make them a preferred choice in many industries. Proper selection of valves is essential to ensure efficient and reliable system operation.

Bends

Bends are PVC pipe fittings used to change the direction of piping systems at specific angles. They are available in various configurations‚ such as 45°‚ 60°‚ 90°‚ and 180°‚ depending on the application. PVC bends are lightweight‚ corrosion-resistant‚ and durable‚ making them ideal for water supply‚ drainage‚ and irrigation systems. They are manufactured from high-quality PVC materials and are designed to withstand various pressure ratings‚ including 6 kg/cm²‚ 8 kg/cm²‚ and higher. Bends are easy to install using solvent welding or other common PVC fitting techniques‚ ensuring a leak-proof connection. Their smooth inner surfaces minimize flow resistance‚ maintaining system efficiency. Proper selection of bends is crucial to ensure the system’s functionality and longevity. They are widely used in residential‚ commercial‚ and industrial applications where reliable and long-lasting performance is required.

Reducers

Reducers are PVC pipe fittings used to connect pipes of different diameters‚ ensuring a smooth transition between them. They are essential in plumbing and piping systems where changes in pipe size are necessary. Available in various types‚ such as concentric and eccentric reducers‚ they are designed to maintain flow efficiency and minimize pressure loss. PVC reducers are lightweight‚ corrosion-resistant‚ and durable‚ making them suitable for water supply‚ drainage‚ and irrigation systems. They are manufactured to meet specific pressure ratings‚ including 6 kg/cm²‚ 8 kg/cm²‚ and 10 kg/cm²‚ depending on the application.Reducers are easy to install using solvent welding or other common PVC fitting techniques‚ ensuring a leak-proof connection. Their smooth inner surfaces help maintain system efficiency‚ and they are widely used in residential‚ commercial‚ and industrial applications where reliable performance is required.

Caps

Caps are PVC pipe fittings used to seal the ends of pipes‚ preventing leakage and protecting the system from contaminants. They are simple yet crucial components‚ offering a secure and watertight seal. PVC caps are available in various sizes to fit different pipe diameters and are manufactured to meet specific pressure ratings‚ ensuring durability and reliability. Their corrosion-resistant properties make them ideal for use in water supply‚ drainage‚ and irrigation systems. Installation is straightforward‚ typically involving solvent welding or threading‚ depending on the type of cap. PVC caps are lightweight‚ easy to handle‚ and provide a cost-effective solution for terminating pipes in residential‚ commercial‚ and industrial applications. They are also included in comprehensive PDF guides that detail names and images of PVC pipe fittings‚ aiding in identification and selection for various projects.

Plugs

Plugs are essential PVC pipe fittings designed to seal pipe openings temporarily or permanently. Unlike caps‚ plugs are typically inserted into the pipe end‚ providing a secure and leak-proof connection. They are commonly used in plumbing and industrial applications to block flow during maintenance or testing. PVC plugs are available in various types‚ including threaded‚ solvent-weld‚ and push-fit models‚ catering to different system requirements. Their corrosion-resistant and durable nature makes them suitable for use in harsh environments. Plugs are often included in PDF guides that list names and images of PVC pipe fittings‚ helping professionals and DIYers identify and select the appropriate plug for their specific needs. Proper installation ensures system integrity and long-term performance‚ making plugs a vital component in piping systems.

Unions

Unions are versatile PVC pipe fittings that allow for the quick connection and disconnection of pipes without the need for tools. They are commonly used in plumbing and industrial systems to provide flexibility and ease of maintenance. PVC unions typically consist of a male and female threaded end‚ with a central nut that secures the connection. Their design makes it easier to install‚ inspect‚ or replace pipes and components. Available in various sizes and pressure ratings‚ unions are suitable for both low and high-pressure applications. They are often highlighted in PDF guides that provide names and images of PVC pipe fittings‚ offering a clear visual and functional understanding for professionals and DIY enthusiasts. Their durability and resistance to corrosion ensure long-term reliability in diverse piping systems.

Flanges

Flanges are circular PVC pipe fittings used to connect pipes‚ valves‚ or other equipment in plumbing and industrial systems. They are secured using bolts and gaskets‚ ensuring a leak-tight seal. PVC flanges are lightweight‚ corrosion-resistant‚ and ideal for low-pressure applications. They are available in various types‚ including slip-on‚ socket weld‚ and threaded flanges‚ catering to different connection needs. PDF guides often include detailed names and images of PVC flanges‚ helping professionals identify the right fitting for their projects. These fittings meet international standards like ANSI B16.5 and are used in water supply‚ irrigation‚ and chemical systems. Their durability and ease of installation make them a popular choice for both residential and industrial piping setups. Always refer to manufacturer specifications for size and pressure ratings to ensure compatibility and safety.

Applications of PVC Pipe Fittings

PVC pipe fittings are widely used in plumbing‚ irrigation‚ and industrial systems due to their durability and resistance to corrosion. They are ideal for water supply‚ drainage‚ and HVAC systems‚ offering reliable connections in various environments; PDF guides often highlight their versatility and suitability for different applications‚ making them a preferred choice for both residential and commercial projects.

Plumbing Systems

PVC pipe fittings are integral to modern plumbing systems‚ providing durable and corrosion-resistant connections for water distribution and waste management. Their versatility allows them to be used in both residential and commercial settings‚ ensuring reliable water flow and drainage. PDF guides often detail the various types of PVC fittings‚ such as tees‚ elbows‚ and couplings‚ which are essential for creating complex pipe networks. These fittings are resistant to chemicals and can withstand varying water pressures‚ making them a preferred choice for plumbers. Additionally‚ their ease of installation and low maintenance requirements contribute to their widespread use in plumbing systems worldwide.

Irrigation Systems

PVC pipe fittings play a crucial role in irrigation systems‚ enabling efficient water distribution for agricultural and landscaping needs. They are resistant to corrosion and UV light‚ making them ideal for outdoor use. PDF guides often showcase fittings like tees‚ elbows‚ and couplers‚ which are vital for designing and maintaining irrigation networks. These fittings allow for customization‚ ensuring water reaches every part of the field or garden. Their durability and resistance to chemicals ensure long-term reliability‚ even in harsh environments. Farmers and landscapers rely on PVC fittings to optimize water usage and maintain system performance‚ making them indispensable in modern irrigation practices.

Industrial Applications

PVC pipe fittings are widely utilized in industrial settings due to their chemical resistance and durability. They are ideal for systems handling corrosive substances‚ acids‚ and harsh chemicals‚ where traditional materials like metal would fail. PDF guides detail a variety of fittings such as unions‚ flanges‚ and valves‚ which are essential for creating leak-tight connections in industrial piping. These fittings are also lightweight‚ making them easier to install and maintain compared to metal alternatives. Their resistance to abrasion and ability to withstand high pressures make them suitable for demanding environments. Industries like manufacturing‚ oil and gas‚ and chemical processing rely on PVC fittings to ensure safe and efficient operation of their systems‚ reducing the risk of contamination and equipment damage;

Drainage Systems

PVC pipe fittings play a crucial role in drainage systems‚ offering a reliable and durable solution for waste and stormwater management. Their resistance to corrosion and chemicals ensures longevity in underground and above-ground applications. PDF guides provide detailed information on fittings like bends‚ tees‚ and couplings‚ which are essential for directing and connecting pipes in drainage networks. PVC fittings are lightweight‚ making them easier to transport and install compared to traditional materials. They also feature smooth inner surfaces‚ reducing the risk of clogs and ensuring efficient flow. PVC pipe fittings are widely used in both residential and commercial drainage systems‚ including sewerage and rainwater harvesting setups‚ due to their cost-effectiveness and ease of maintenance.

HVAC Systems

PVC pipe fittings are increasingly used in HVAC (Heating‚ Ventilation‚ and Air Conditioning) systems due to their corrosion resistance and lightweight design. They are particularly suitable for ductwork and ventilation applications‚ where durability and ease of installation are critical. PVC fittings‚ such as elbows‚ tees‚ and couplings‚ are commonly used to connect and direct airflow in HVAC systems. Their smooth inner surfaces minimize resistance‚ ensuring efficient air circulation. PVC pipe fittings are also resistant to moisture and chemicals‚ making them ideal for environments exposed to humidity or harsh conditions. A PDF guide on PVC pipe fittings provides detailed names and images of components‚ helping technicians and installers select the right parts for HVAC applications. This resource is invaluable for ensuring proper system design and functionality.

Technical Specifications of PVC Pipe Fittings

PVC pipe fittings are manufactured in various sizes and pressure ratings‚ with specifications detailed in PDF guides. They offer excellent chemical resistance and durability‚ suitable for diverse applications.

Dimensions and Sizes

PVC pipe fittings are available in a wide range of dimensions and sizes to accommodate various applications. Common diameters include 16mm‚ 20mm‚ 25mm‚ and up to 225mm‚ ensuring compatibility with different piping systems. The fittings are designed to match standard pipe sizes‚ making installation straightforward. Detailed tables in PDF guides outline specific measurements for tees‚ elbows‚ couplings‚ and adapters‚ providing precise data for engineers and plumbers. These resources also include dimensional charts to help users verify compatibility and ensure accurate fitting selections. Proper sizing is crucial for maintaining system integrity and performance‚ making these guides invaluable for both professionals and DIY enthusiasts;

Pressure Ratings

PVC pipe fittings are designed to withstand specific pressure ratings‚ ensuring reliability in various applications. Common ratings include 6 kg/cm²‚ 8 kg/cm²‚ and 10 kg/cm²‚ with higher ratings available for specialized uses. These ratings are clearly marked on the fittings and detailed in PDF catalogs‚ providing essential information for system design. Proper selection based on pressure requirements prevents failure and ensures long-term performance. The pressure ratings are tested to meet international standards‚ guaranteeing safety and durability across different environments. Always refer to manufacturer specifications to ensure fittings match system demands‚ especially in industrial or high-pressure applications where failure can have severe consequences.

Temperature Ratings

PVC pipe fittings are suitable for a range of temperatures‚ typically between 0°C to 60°C‚ making them ideal for standard plumbing and drainage systems. Higher temperature applications may require specialized PVC compounds. The PDF guide provides detailed temperature limits for each fitting type‚ ensuring proper material selection. Exposure to extreme heat can compromise the structural integrity of PVC‚ leading to potential failures. Therefore‚ it’s crucial to adhere to manufacturer-recommended temperature ranges. For applications involving high temperatures‚ alternative materials like CPVC (chlorinated polyvinyl chloride) are often recommended. Always consult the product specifications to ensure compatibility with the operating conditions‚ especially in industrial or HVAC systems where temperature fluctuations are common.

Chemical Resistance

PVC pipe fittings are renowned for their excellent chemical resistance‚ making them ideal for systems handling acids‚ alkalis‚ and other corrosive substances. They are widely used in industrial applications where exposure to harsh chemicals is common. However‚ PVC is not suitable for solvents like ketones or chlorinated hydrocarbons‚ as they can cause material degradation. The PDF guide provides detailed information on the chemical compatibility of PVC fittings‚ ensuring proper selection for specific environments. This feature makes PVC fittings a cost-effective and durable choice for plumbing‚ drainage‚ and industrial systems. Regularly referencing the guide helps in maintaining system integrity and avoiding material failures due to chemical exposure.

Installation and Maintenance

PVC pipe fittings require proper solvent welding and ANSI-standard connections for secure installation. Regular maintenance ensures longevity and prevents leaks. Always follow safety guidelines during handling.

Installation Methods

PVC pipe fittings are typically installed using solvent welding‚ a method that creates a strong‚ leak-proof bond between pipes and fittings. This process involves applying a solvent cement to both the pipe and fitting‚ then quickly assembling them before the cement dries. Additionally‚ mechanical connections such as flanges or unions can be used for systems requiring frequent disassembly. Proper alignment and cleaning of surfaces are critical for a secure seal. Tools like pipe cutters and primer are essential for preparation. Always follow ANSI B16.5 and ASTM standards for installation to ensure compliance and safety. Testing with compressed air is recommended to verify system integrity‚ but avoid using gas due to explosion risks. Environmental factors‚ such as temperature and pipe alignment‚ must also be considered for optimal results.

Maintenance Tips

Regular maintenance is crucial to ensure the longevity and performance of PVC pipe fittings. Inspect fittings for signs of leaks‚ cracks‚ or mineral buildup‚ addressing issues promptly to prevent system failures. Clean fittings with mild detergents and water to remove dirt and debris. Avoid using harsh chemicals or abrasive materials that could damage the PVC surface. Properly secure connections and ensure they are not overtightened‚ as this can cause warping or cracking. Regularly check for corrosion on metal components‚ such as flanges or valves‚ and replace them if necessary. Store unused fittings in a cool‚ dry place‚ away from direct sunlight and extreme temperatures. Follow manufacturer guidelines for maintenance and repairs‚ and consider consulting a professional for complex systems. Proper care ensures PVC fittings remain durable and reliable over time.

Safety Considerations

When handling PVC pipe fittings‚ prioritize safety to avoid accidents and ensure system integrity. Always wear protective gear‚ including gloves and safety glasses‚ to prevent injuries from sharp edges or debris. Avoid testing or using compressed air or gas in PVC systems‚ as this can lead to explosive failures and severe harm. Use solvent cements and primers in well-ventilated areas to prevent inhaling harmful fumes. Follow proper joining techniques to avoid weakening the pipe structure‚ which could result in leaks or bursts under pressure. Never exceed the recommended pressure or temperature ratings for PVC fittings‚ as specified in the PDF guide. Properly secure fittings during installation to prevent shifting or dislodgment. Keep flammable materials away from solvent-welded joints until fully cured. Adhere to local plumbing codes and manufacturer instructions for safe and reliable system operation;

Resources for Further Learning

Download a PDF guide with names and images of PVC pipe fittings for detailed insights. Manufacturer websites like ERA and Bina Plastic offer catalogs and technical specifications for further reference.

PDF Guides and Catalogs

Comprehensive PDF guides and catalogs are available for PVC pipe fittings‚ providing detailed information on names and images. These resources‚ such as those from ERA and Bina Plastic‚ include specifications‚ dimensions‚ and installation tips. They serve as valuable tools for professionals and DIY enthusiasts‚ ensuring accurate component selection and proper usage. Manufacturers often offer downloadable versions‚ making it easy to access technical data and product details. These guides are essential for understanding the wide range of PVC fittings available and their applications in various systems.

Manufacturer Websites

Manufacturer websites are invaluable resources for detailed information on PVC pipe fittings. Companies like Iplex‚ ERA‚ and Bina Plastic provide comprehensive catalogs and technical specifications. These sites often include PDF guides with names and images of fittings‚ ensuring easy identification and selection. Many manufacturers offer downloadable resources‚ such as product brochures and certification details‚ which highlight compliance with international standards like ISO‚ CE‚ and NSF. Visitors can explore product ranges‚ including PVC-U‚ PPR‚ and HDPE systems‚ tailored for plumbing‚ drainage‚ and industrial applications. These websites serve as one-stop platforms for professionals and DIY enthusiasts‚ offering insights into product features‚ pressure ratings‚ and installation guidelines. They are essential for making informed decisions and sourcing high-quality PVC pipe fittings.